Structure

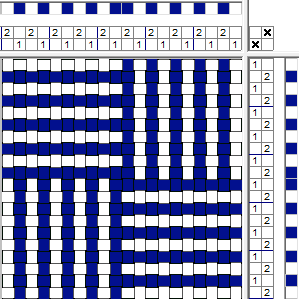

#47 from A Weaver’s Book of 8-Shaft Patterns, edited by Carol Strickler. Colorado: Interweave Press, 1991 (p. 17).

This is a crepe weave of the sort that are “drafted by dividing the tie-up into quadrants, designing one quadrant and then rotating or inverting or reversing it into the other three sections.” (Strickler p. 10). Diane Ferguson wove #47 for the book in white on white and recommended that it looked the best when warp and weft were identical.

Like anyone who ever tried a recipe on the Internet, I did not follow instructions. I went for 8 dark X 8 light color and weave. On the loom, the color combination produces rectilinear checks much like the drawdown shown in Figure 1. With finishing, the yarns in their variable floats find new positions of rest and create a diamond effect on the fabric surface.

Draft

The tie-up is for sinking shed. Strickler gives a rising shed tie-up.

Equipment

8-shaft loom

Reed for 20 epi

2 shuttles, or more for more colors

Yarn

Warp and Weft: 6/2 cotton from Bluegrass Mills (2520 yds/lb)

Sett

Warp: 20 ends per inch

Weft: 20 picks per inch

Dimensions

Warp shrinkage: 15%

Weft shrinkage: 17%

For shrinkage calculations, the prefinished measurements are taken on the loom: 1) the length of the towel as measured by a paper measuring tape pinned to the weaving, 2) the width of the weft in the reed. After cutting off, I sewed the cloth end to end into a loop and ran it through the washer and the dryer in a full load. Measurements were taken after finishing but before cutting each unit for hemming.

Weaving

The weaving is touchy because the density of interlacements varies. Each repeat begins and ends with a shot of plain weave. These shots tolerate a stiff beat whereas the other six shots have two to four end floats that cross two to four end floats in the warp. When I sampled at 18 ends per inch, the diamonds flattened. At 20 ends per inch, I could square them up with a light beat.

I chose to beat firmly on the plain weave shots, which gave even density to the cloth. Beating lightly on the second plain weave shot could create lacelike space between the repeats.

Experiments and Results

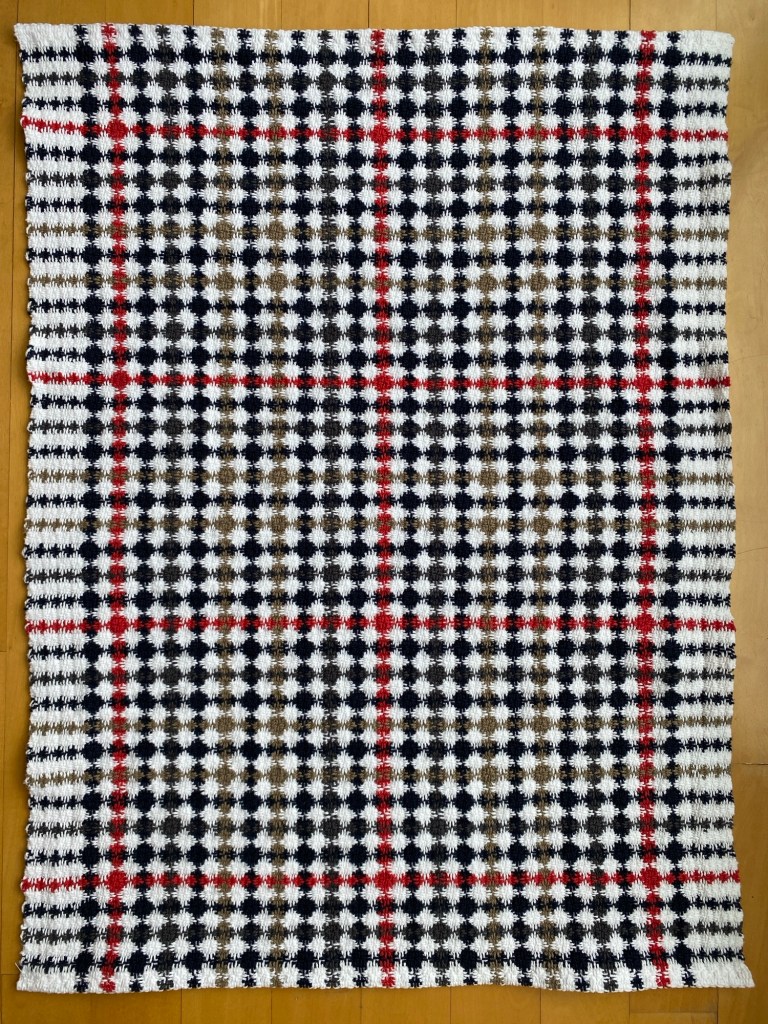

Color and Weave

This sample shows the effect of light against dark as well as the effect of crossing two dark yarns of similar value but different hue: pink on green. In two colors, the neat diamonds lose their visual coherence. They are tolerable because they make fields of solid pink and solid green diamonds possible in the same cloth, but the mixed color diamonds are not a primary effect. If I were to mix colors again, I would switch colors in the warp and weft after every six or seven repeats to weave a checkered grid of 4 X 4 inch squares.

Log Cabin – negative results

If you look hard, my sample shows that I tried to weave log cabin in this Light Dark (8L8D) color scheme. Log cabin is a color and weave stripe effect that happens in plain weave through shifting the color order.

Figure 2 shows how shifting LDLD to DLDL changes the interaction of light and dark warp and weft on the surface of the fabric to create warp-wise and weft-wise stripes.

Because I was working with a Light Dark combination that had an unexpected interaction, I thought it might go all log cabin if I set up the color order properly. In the green and white areas of weaving, there is a double green stripe of diamonds where I shifted the warp color order from 8L8D – 8D8L. In the pink and white areas of weaving, there is a double white stripe where I shifted the warp from 8D8L – 8L8D. But no extra interactions emerged.

In Color-and-Weave II (1994), Margaret Windeknecht explained the principle on which warp- and weft-wise stripes appear in five-point twill checks. For two blocks, A and B, “the effect in Block B is identical to that on the reverse side in Block A. In a sense, you are weaving face and reverse on the same side of the fabric” (p. 69). For Strickler #47 threaded 8D 8L, the diamonds are created on both sides by the crossing of 8L with 8L and 8D with 8D. The face and reverse are identical and the simple shift that I attempted has no effect on the interaction of colors.

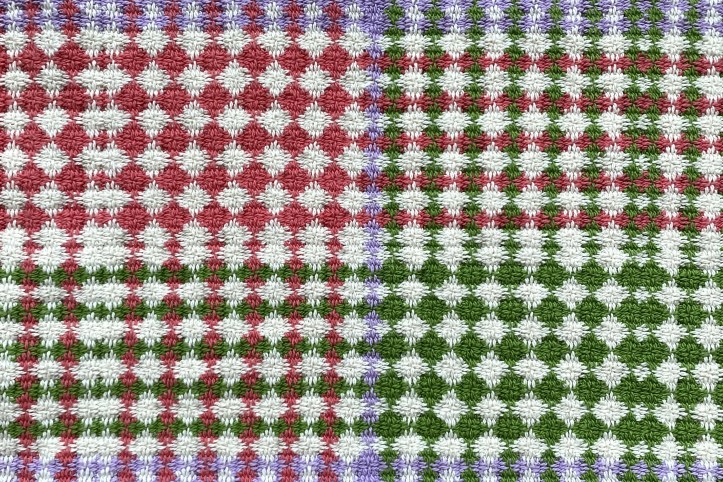

Weaving software shows that LDLD – DLDL color order applied to #47 creates Blocks A and B that are not quite opposite (Figure 3). B is a 90o counterclockwise rotation of A. Blocks A and B’ are opposites as are B and A’. The appearance of the drawdown suggests that this effect might lend itself to high-contrast motifs that reverse on the diagonal. Because of the rearrangement of yarns in washing, sampling would be needed to determine whether an effect like this is pleasing.

Untested Lace Idea

If I were to warp this up again, I would sample a new denting scheme to bring light or air to the space between each square. Using a 10 dent reed, I would sley 1-8 at 20 ends per inch and then leave a dent empty between repeats. When weaving, I would beat to square on treadles 2-8, but beat lightly on 1 to leave space between repeats.

Acknowledgements

My original idea for Strickler #47 in 8D8L color came from Pat Bullen’s multicolor towel that won First Place for Color in the 2020 Woolery Weave-off. https://woolery.com/our-blog?p=woolery-weaveoff-winners-2020